How Does Plastic Extrusion Work?

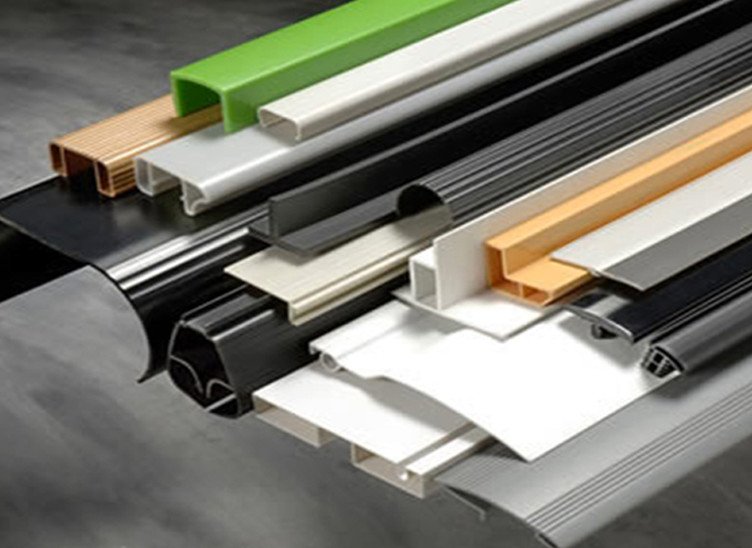

Plastic extrusion involves melting plastic into solid, finished products such as pipes and tubing. Understanding how extrusion methods work helps determine which technique fills a business’s needs. Some processes include co or tri-extending, which can produce a wide variety of shapes, forms, and textures. At Clark Rubber and Plastic, we provide plastic extrusion services for products used in various industries. Here’s how our process works:

Heating

Our team at Clark Rubber and Plastic uses various types of plastic for extruding, including PVC, acrylic, and TPU. We start the process by heating the materials to create a specific product for a business’s needs, whether it’s automotive or solar parts. Our manufacturers may also add colorants or stabilizers to the melted mixture to enhance its final quality.

Heating occurs as the plastic pellets fed into the melting chamber are pulled along by a revolving screw. The friction caused by the movement increases the pressure and generates heat, leading to melting. A filter screen sits at the end of the melting chamber, which removes impurities from the melted plastic as it is pushed through.

Shaping

The melted plastic is pushed out of the barrel chamber through a die, which sets the final shape of the extruded product. Some common plastic products created through extruding include bars, pipes, wire insulation, and monofilaments. Plastic extrusion also creates products with custom profile features like edges and channels. Co- and tri-extruding can create items made with different components or incorporating different colors. In both processes, the materials composing the outer layers are of high quality to help the finished product be more stable.

Some shrinkage can occur during the extruding process and is more common with complex profiles. Designers may overcome this by being generous when sizing a die, allowing a small amount of extra space in the mold to account for shrinkage. Additional shearing can be done later on the production line to maintain uniform sizing.

Cooling

The shaped plastic profile is set through cooling, finalizing the product’s form. This process happens as belts pull the profile through a long trough containing a cold water bath. Certain products, such as plastic pipes, might require additional mechanisms that remove heat in order to keep their shape. Designers may apply a vacuum to the water bath to keep the pipe from collapsing as it cools.

The belts pulling the profile along also help to correctly size the cooled profile, satisfying the client’s required dimensions. The sizing belt pulls the profile through a final opening, at the end of which a blade slices it into individual pieces. These are the completed products that are then sent on to users.

Your Partner in Plastic Extrusion

The plastic extrusion process requires a tightly controlled environment to deliver quality products. At Clark Rubber and Plastic, our professional extrusion services deliver the precise results needed for products to meet industry standards. Our team has extensive experience and access to the necessary production capacity to fulfill almost any request. Contact us today for a quote on your next job.

Different Plastic Extrusion Techniques

Plastic extrusion is a high-volume manufacturing process that involves pushing melted plastic through a die so that the plastic takes on a new shape. This process can create a wide range of plastic products with various shapes, profiles, sizes, and properties. It is also highly customizable and cost-effective, making it a good option for large-scale production runs and custom projects. There are multiple plastic extrusion techniques used for different applications, including:

Co-extrusion

Co-extrusion combines two materials with different properties into a single cross-section. The process uses two extruders to extrude multiple layers of material simultaneously. These extruders can be set to different speeds and sizes to alter the layer thicknesses. Our manufacturers use co-extrusion to produce products with various performance characteristics, including enhanced durability and strength.

Clark Rubber and Plastic can also complete projects that require tri-extrusion. Tri-exclusion is similar to co-extrusion but uses three extruders and separate materials. This allows our manufacturers to customize your product to your desired specifications.

Tubing Extrusion

We use tubing extrusion to produce plastic tubes and pipes with uniform dimensions and properties. This process often requires the extruder to push a positive internal pressure throughout the plastic to create a hollow core. Tubing extrusion can create pipes for medical devices and plumbing applications because it produces tubes with precise tolerances, smooth surfaces, and consistent quality.

Blow Film Extrusion

Our manufacturers use blow film extrusion to produce thin plastic films with uniform thickness, such as shopping bags and food packaging. The melted plastic is extruded through a circular die to create a tube during the extrusion process. The machine then uses air pressure to inflate the tube to the desired size and thickness. We can customize these specifications to fit the diverse needs of various industries and applications.

Sheet Extrusion

The sheet/film extrusion method produces flat plastic sheets of varying thicknesses. It may be used to produce plastic films or sheets that are too thick to be made with blow film extrusion. During extrusion, molten plastic is extruded through a flat die, which is then cooled to form a continuous sheet. Sometimes, the sheets go through a series of cooling rolls, which can control sheet thickness. We use these sheets to create various products, including signs or packaging materials.

Over-Jacketing Extrusion

Our manufacturers use over-jacketing extrusion to apply an additional protective coating to something, most often a cable or wire. In this method, the machine extrudes a layer of melted plastic material over the surface of the cable. This helps provide enhanced insulation and durability, increasing the wire’s reliability and safety.

Contact Clark Rubber and Plastic for Plastic Extrusion Services

Plastic extrusion creates plastic products with precision and efficiency. Each technique is better suited for different applications and has unique advantages. Clark Rubber and Plastic has expanded its plastic capacity to accommodate multiple projects using different extrusion techniques. We work with you to understand your project’s demands so we can recommend materials and design options. We have experience with many industries, including solar, appliances, automotive, and more. Contact us today to learn more about our services.

Exploring the Benefits of Plastic Extrusion

Plastic extrusion is a manufacturing process that produces a wide variety of plastic profiles, forms, and shapes. These shapes are created by running melted plastic through an opening in a die and trimming the product to the desired length. At Clark Rubber and Plastic, our services are used in various industries, including solar, consumer, appliances, and automotive. Here are some of the benefits of plastic extrusion:

Cost-effective

Plastic extrusion is more cost-effective than many other manufacturing methods. Thermoplastics are generally less expensive than other materials, such as metals. The process itself is high-volume and produces minimal material waste, so the production cost per unit is relatively low. It is also highly streamlined and mechanical, which reduces labor requirements and associated costs. These factors make it an attractive option for manufacturers who want to drive down unit costs without sacrificing quality.

Versatile

Extrusion allows you to create products with customized shapes, sizes, and properties. Many materials are available, including PVC and polyethylene. The material you select can affect the thickness, texture, and hardness of your product. This versatility allows manufacturers to create customized products and develop solutions that meet their unique needs and applications. It also gives them options and enables them to make changes to their design if needed.

Efficient

The machines we use for our plastic extrusion services can run continuously with less supervision. This allows us to make large quantities of products in a short period of time, contributing to a high output rate and reducing the risk of inventory shortages. The ability to customize extrusion parameters such as die design, temperature, and pressure also allows manufacturers to tailor the process to their specific requirements. This can further enhance efficiency and minimize production costs.

Consistent

The plastic extrusion production process is known for producing consistent results. It regularly delivers products with precise dimensions, high-quality finishes, and uniform properties. The continuous shaping of molten plastic through the die creates consistent cross-sectional profiles throughout the length of the extrudate. This allows manufacturers to achieve tight tolerances and develop products that meet industry specifications and standards.

Sustainable

Many thermoplastic materials used in extrusion, such as polyethylene, are recyclable and can be reused. This minimizes waste and conserves resources. The process can also prevent unnecessary waste of resources such as electricity and other process materials. The efficiency of the process, combined with advancements in recycling technology and energy-efficient machinery, allows manufacturers to reduce energy consumption and carbon emissions.

Co-extrusion Capabilities

Co-extrusion is the process of extruding two or more different polymers simultaneously to create complex products with varying properties. Different materials can contribute specific functionalities, such as strength, flexibility, and barrier properties. This capability allows manufacturers to create unique products and increase functionality. It also offers greater design flexibility and improved cost-efficiency, offering a competitive advantage in the market.

Request a Quote for Plastic Extrusion Services

Plastic extrusion offers many benefits for various industries. Its efficiency, consistency, and cost-effectiveness make it an ideal choice for producing a wide range of plastic products, including plastic sheets and tubing. Clark Rubber and Plastic takes the time to understand your product’s demands and your industry’s requirements and standards. We use this information to recommend materials and design options. Contact us today to learn more about our extrusion options and services.

6 Common Applications of Plastic Extrusion

Plastic extrusion is used to create continuous lengths of plastic products with a consistent cross-section. At Clark Rubber and Plastic, we offer extrusions that can be used in various applications and industries. Some suitable applications include solar, automotive, and appliances. Here are six common applications of this type of extrusion:

1. Solar Industry

Plastic extrusion plays a role in producing components like solar panel frames and encapsulation materials. Extruded plastics’ lightweight and durable nature can make them ideal for supporting solar modules. This promotes the solar device’s longevity and resistance to environmental elements. Our process allows companies to create customized profiles, enabling them to meet the specific design requirements of solar installations.

2. Automotive Sector

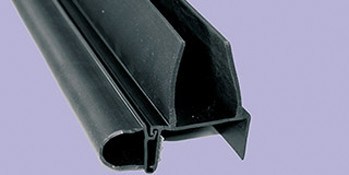

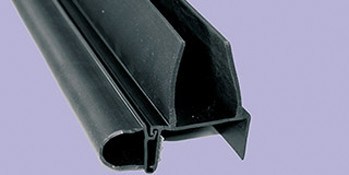

Extruded plastic manufacturing is applied in the automotive industry, as it contributes to the production of several automotive parts. Items like weather seals, gaskets, and interior trim components may use these extrusions. Vehicle tubing and hoses for fluid transfer systems also utilize extruded plastic. The manufactured parts offer resistance to chemicals, temperature variations, and UV exposure. This can increase durability in diverse automotive applications. At Clark Rubber and Plastic, we use extrusion to produce complex shapes and precise densities for the automotive sector.

3. Appliance Manufacturing

The appliance industry benefits from plastic extrusion in the production of components such as gaskets, seals, and handles. Extruded plastics provide insulation and sealing properties, enhancing the energy efficiency of appliances. The cost-effectiveness of the extrusion process allows us to produce high volumes of consistent parts. This can help us meet the demands of the appliance market while maintaining quality standards.

4. Construction Industry

Extruded plastic manufacturing is applied in the construction industry. The parts can be seen in windows, doors, and other architectural elements. Extruded plastics are versatile, enabling the production of weather-resistant and thermally efficient profiles. This can contribute to sustainable and energy-efficient building practices. The lightweight nature of extruded plastic components also simplifies installation processes, which may reduce overall construction time.

5. Medical Device Manufacturing

Plastic extrusion can be utilized to manufacture tubing, catheters, and various medical device components. The ability to use a wide range of medical-grade plastics helps make sure medical sectors are in compliance with specific regulatory requirements. The extrusion process also fosters complex and intricate profiles, meeting the particular needs of medical applications like microcatheters and guide wires.

6. Packaging Industry

In the packaging industry, companies can use plastic extrusion to help produce films, sheets, and other profiles used for packaging materials. The versatility of extruded plastics allows for the creation of packaging with varying thicknesses, barrier properties, and surface finishes. This adaptability makes plastic extrusion a suitable choice for developing packaging solutions that protect products, extend shelf life, and enhance visual appeal.

Plastic Extrusion

At Clark Rubber and Plastic, we use cutting-edge technology to create high-quality results in our extrusion processes. We can create a variety of profiles, forms, and shapes for your industry. Choose from varying hardnesses, thicknesses, textures, and colors. Contact us today to learn more about our extruded plastic manufacturing processes and applications.

The Differences Between Extrusion and Rolling Plastics

There are two types of processes that can be used to shape raw plastic materials into a product, such as extrusion and rolling. Plastic extrusion can involve various steps, but it helps to create complex shapes while rolling. It’s mainly used to create sheets with specific thickness requirements. Knowing the differences can help you determine what process is best for your plastic manufacturing needs. At Clark Rubber & Plastic, our extrusion services can help you produce shapes and profiles with varying thicknesses, colors, hardness, and textures.

Plastic Extrusion

Extrusion helps the melting plastic through a die, which is a shaped opening. The shape of the die determines the shape of the extruded plastic. We can use extrusion to create various products, including pipes, tubes, sheets, and more. It can also create specific, complex shapes and long, continuous shapes. It is highly versatile and customizable, allowing for custom sizes, shapes, thicknesses, and textures. Extrusion can be fast, efficient, and consistent.

The extrusion process can use highly specialized equipment. We recently added six new extrusion lines to our facility to accelerate our plastic operations and production. This helps us keep up with increased demand and quality requirements. It also makes us more capable of working within your timeline.

Plastic Rolling

This process involves inserting a plastic sheet or film between a series of rollers. These rollers reduce the thickness of the plastic until it meets the client’s desired specifications. The rollers can be textured or smooth, depending on the product requirements. It can also be used to create sheets with a smooth or specific texture. Rolling cannot create complex shapes.

Key Differences Between Extrusion and Rolling

Extrusion and rolling are both effective plastic manufacturing methods. The key differences between these processes can help you determine what process is best for your purposes. Here are a few differences between the two approaches:

Shape and Finish

Extrusion can create a wide variety of shapes. It is also more versatile for creating complex cross-sectional shapes, continuous shapes, and more. The texture and finish are customizable for various specifications. Rolling can create flat sheets, smooth or textured. The thickness and finish are often customizable.

Speed and Efficiency

Plastic extrusion can be a fast and efficient process. This efficiency can also lead to cost savings. Rolling may be slower than extraction with lower efficiency. We optimize our production processes to increase efficiency and reduce waste as much as possible during extraction and rolling.

Waste

Extrusion can produce more waste than rolling because more plastic isn’t used after passing through the die. We mitigate this by feeding a precise amount of plastic into the die. We also help reduce waste by prioritizing efficient production processes and using sustainable practices.

Use Clark Rubber & Plastic for Manufacturing

Clark Rubber & Plastic manufactures rubber and plastic parts for various applications. We serve the automotive, medical, solar, appliance, and military industries. We use some of the most advanced equipment to complete plastic extrusion. If you have a project that requires plastic manufacturing services, contact us today.

The Differences Between Rubber Molding and Plastic Molding

Manufacturing processes like rubber molding and plastic molding play a role in the production of various products we use in our daily lives. These processes might seem similar at first glance, but each has unique characteristics. Here are the differences between rubber and plastic molding.

Rubber Molding

Rubber molding, or rubber compression molding, is primarily used for creating rubber parts and components. This method involves applying heat and pressure to form rubber materials into the desired shape. Several rubber molding processes exist, including compression, transfer, and injection molding.

Rubber casting uses natural rubber, silicone rubber, and synthetic rubber compounds. These materials are elastic and resilient. This makes them ideal for tasks that need flexible and durable items.

The material is heated first in rubber casting, placed in the mold cavity, and exposed to high pressure and heat. Pressure combined with heat vulcanizes the rubber and takes the mold’s shape. Latex molding helps to produce gaskets, tires, and seals in the automotive industry. The process is also standard in making medical devices, industrial machinery, and consumer goods.

Items made through latex molding are durable, resistant to extreme temperatures, and have superior sealing properties. Rubber casting can create complex shapes with intricate details, making it suitable for various applications.

Plastic Molding

Plastic molding is a manufacturing process used to create plastic products. Techniques used in this manufacturing process include injection molding, extrusion, and blow molding. You can use any of these methods depending on the type of plastic material and what you want the final product to look like.

This manufacturing process uses many thermoplastic materials like polypropylene, polyethylene, PVC, and many others. Each type of plastic has its own properties, which influence its suitability for different applications.

Manufacturers choose plastic material to heat to a molten state during plastic molding and then inject, blow, or extrude into a mold cavity. Once it cools and solidifies, the finished product is removed from the mold. Plastic molding is used to produce everything from packaging materials and household items to automotive parts and electronics casings.

Plastic molding processes are highly versatile and efficient. They encourage identical parts to be produced precisely and repeatedly. Plastic components are light, resist corrosion, and are cost-effective to produce.

Differences

- Rubber casting uses rubber materials, while plastic molding uses plastic polymers.

- This manufacturing process uses heat and pressure to shape rubber materials. Plastic molding incorporates the melting and solidifying of plastic materials in a mold.

- Rubber molding suits products that require elasticity, resilience, and resistance to extreme temperatures. You can apply plastic molding in various industries and product categories because it is versatile.

- Plastic molding offers versatility, repeatability, and cost-effectiveness. Rubber casting provides sealing and durability.

Use Our Rubber Molding Services

Rubber and plastic molding are two distinct manufacturing processes catering to specific applications and materials. Understanding the differences helps manufacturers and product designers select the appropriate method for their needs. Contact us today for your rubber molding needs and experience the flexibility of rubber in your everyday lives.

6 Solar Panel Parts and How They’re Made

A solar panel has several parts that work together to convert sunlight to electricity. Many solar panel manufacturers partner with companies that can efficiently produce the required quantity and quality of panel components. At Clark Rubber & Plastic, we provide rubber and plastic extrusion services to make components for various solar panel applications. Here are some of the main solar panel parts and how they are made:

1. Solar Cells

Solar cells are also known as photovoltaic cells and are the heart of a solar panel. They absorb the sun’s energy and convert it into electricity. These cells are typically made from thin layers of semiconducting materials like silicon. The manufacturing process involves cutting the silicon into wafers, doping them with impurities to create the necessary electrical properties, and adding metal contacts to facilitate electricity flow. Solar cells come in various colors, configurations, designs, and technologies.

2. Encapsulation

Encapsulation is the protective barrier between the solar cells and the environment. This prevents water, dirt, dust, and other contaminants from damaging the delicate solar cells. It also protects them from mechanical shocks, vibrations, and temperature fluctuations. Encapsulation is created using ethyl vinyl acetate, or EVA, a durable and flexible polymer. The EVA is layered over the solar cells, then heated and laminated to create a protective layer.

3. The Junction Box

A junction box houses electrical connections and protects them from environmental factors. You can find this box on the backside of the solar panel. The junction box contains diodes that prevent reverse current flow and facilitate the wiring of multiple panels in an array. Junction boxes are made from durable plastic. Our rubber and plastic extrusion services can provide the components needed to make these junction boxes. These components include electrical coverings, cable trays and inserts, and other protective parts.

4. Backsheet

The backsheet is the bottom layer of the solar panel that protects it from moisture and provides electrical insulation. Backsheets can be made from different plastics or polymers, each offering varying grades of UV resistance, thermal stability, and protection. The process of creating a backsheet involves extruding the polymer into thin sheets and laminating them onto the panels. Our rubber and plastic extrusion services can provide the high-quality materials needed for this solar panel component.

5. Tempered Glass

A sheet of tempered glass covers the front surface of a solar panel. This glass provides protection against weather conditions, UV radiation, and physical impacts while allowing sunlight to pass through to the cells. Tempered glass is typically made by heating and cooling regular glass in a controlled manner to increase its strength and durability.

6. Frame

The frame is what holds all the components of a solar panel together. It provides structural support and protection for the panel. The frame also facilitates solar panel installation by offering mounting points. Aluminum is the material solar manufacturers prefer for this purpose due to its lightweight, corrosion-resistant, and easy-to-fabricate properties.

Contact Clark Rubber & Plastic for Rubber and Plastic Extrusion Services

Solar panels require various rubber and plastic parts. At Clark Rubber & Plastic, we offer rubber and plastic extrusion services to help solar panel manufacturers get the needed parts for their projects. Whether you require large, small, or complex designs, we have the resources to fulfill your extrusion product requirements. Contact us today to discuss your project and learn more about our extrusion services.

Rubber and Plastic Manufacturing for Home Appliances

The materials used to manufacture home appliances determine their function and dependability. At Clark Rubber and Plastic, we understand the importance of quality materials for home appliance production. We are a plastic manufacturer that provides reliable rubber and plastic products to retailers in various industries, including home appliance companies.

Methods for Manufacturing Rubber and Plastic for Home Appliances

We use specialized processes and techniques to create the highest quality rubber and plastic components for home appliance production. Our methods include:

Plastic Injection Molding

We use high-precision plastic injection molding machines to create plastic components for home appliances such as washers and dryers, refrigerators, and dishwashers. The process utilizes melted plastic and a mold to create precise components that meet the product design specifications. Some of the plastics we produce through plastic injection molding include polycarbonate, nylon, HDPE, ABS, and thermoplastics.

Plastic Extrusion

Plastic extrusion produces continuous lengths of plastic parts used in appliances such as cooktops, microwaves, ovens, and other kitchen appliances. We are a high-quality plastic manufacturer with equipment that can co- or tri-extrude, meaning it can combine two or three materials into a single product. We use various certified grades of materials to create the highest-quality components for home appliance production.

Rubber Molding

Rubber injection molding produces rubber components for appliances such as power cords, hoses, sealing gaskets, and seals. It is a process used to create products that have intricate shapes and require a high level of precision. We use hot and cold rubber molding to create products such as Neoprene, Viton, EPDM, Nitrile, and SBR.

Rubber Extrusion

Rubber extrusion is a process that produces continuous lengths of rubber components for appliances. Our equipment can make complex shapes with high levels of accuracy and precision. We rely on custom dies instead of presses to create rubber components for appliances such as air conditioners, washing machines, and dishwashers. Our specialists can produce rubber parts with various durometers, textures, and colors.

Quality Assurance and Testing

Our products are designed and manufactured with quality in mind, so we have stringent testing and quality assurance procedures. We use advanced inspection methods, including:

Ultrasonic Testing

We use ultrasonic testing to inspect rubber and plastic components for any defects or irregularities. The process involves using high-frequency sound waves to detect flaws in the material before it’s approved for production. It’s a non-destructive test where we can quickly and accurately identify any potential issues. The process is also used to inspect components for dimensional accuracy.

Tensile Testing

The components we create for home appliance production must undergo tensile testing to determine their strength and durability. We use specialized equipment to test the components for any signs of weakness, and if they do not meet our strict standards, they are rejected. Our products are meant to endure the rig of appliance use, and our rigorous testing supports their dependability.

Chemical Analysis

Chemical analysis tests for any inconsistencies or anomalies in the material. Our experts analyze the chemical composition of the materials to determine the best grade and type of plastic or rubber for each application. We also test for any potential risks or hazards that could arise from using certain types of materials.

Get Quality Home Appliance Components From a Reliable Plastic Manufacturer

At Clark Rubber and Plastic, we know that the quality of home appliance components determines their performance and longevity. We take great care in producing the highest-quality components for any home appliance product. Contact us today for reliable, quality parts for your home appliance projects. Our professionals will work with you to customize a solution that meets your exact needs.

- 1