Plastic and Rubber Components for the Solar Industry

Manufacturing products in the solar industry has a number of unique demands and requirements that must be met before those products can go to market. This process can be met simply when you have a manufacturing partner who can provide the quality and quantity of components that you need.

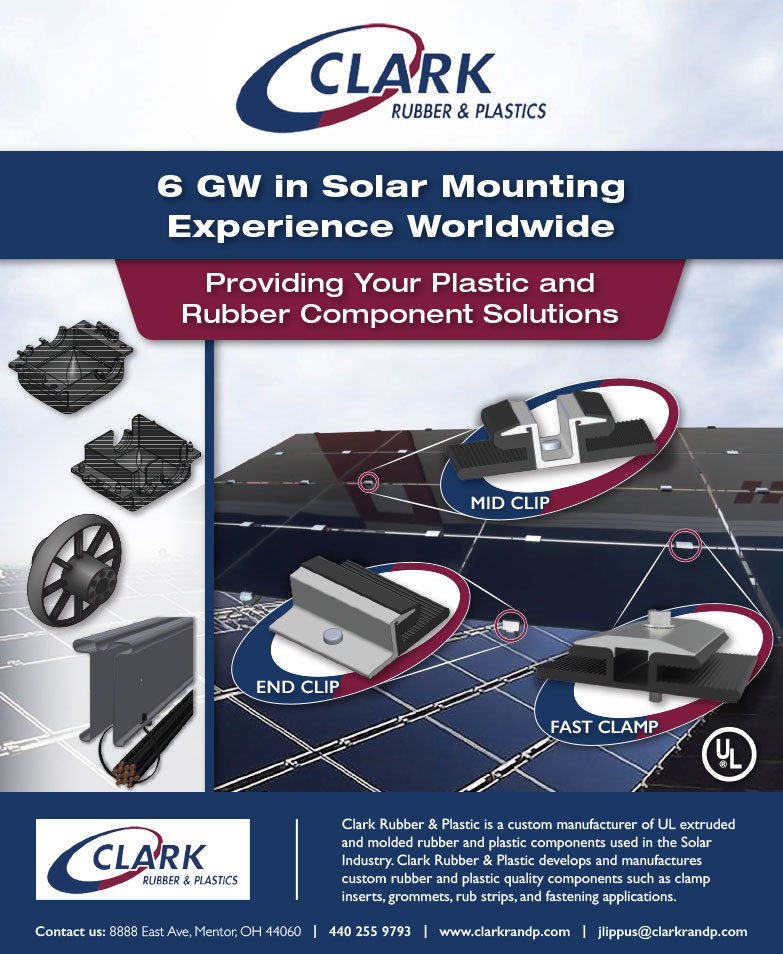

The demand for alternative energies continues to grow, creating great opportunities for companies that can deliver on these demands. Clark Rubber & Plastic is a world-class rubber and plastics manufacturer with extensive experience in the solar industry, and we can provide the components that satisfy the demands of this highly regulated industry.

Precision Manufacturing for Quality Results

At Clark Rubber & Plastic, we offer a wide variety of solar plastics and rubber components for solar applications. We use a wide range of materials and the most effective manufacturing technologies so you can deliver more durable, efficient, and cost-effective solar panels.

These plastic and rubber parts will help to block out rain, dust, and other particles while maintaining the overall structural integrity of the solar equipment.

We can provide:

- Solar Panel Rubber Inserts

- Clamp Insert Assembly

- Plastic Insert

- Rubber Insert

- Fast Clamp Inserts

- Solar Frameless Clip Assembly

- Cable Trays

- Cable Inserts

- Electrical Coverings

These components are made from a wide range of plastic and rubber materials, including Non Conductive EPDM, EPDM, TPV, Viton®, SBR, HDPE, Polycarbonate and a full range of thermoplastics and other engineered materials.

A Performance Advantage

Rubber and plastic components in solar structures can greatly reduce the material and manufacturing costs over metal components. They also lead to a lower overall weight and reliable corrosion resistance.

The right parts can increase the efficiency of solar cells so users can get a longer usable lifetime from them while the manufacturer can reduce the overall costs. They are lighter, easier to work with, and feature high and low-temperature resistance.

At Clark Rubber & Plastic, we have the tools and technology to manufacture custom molded rubber products for nearly any solar industry function, whether you need large or small parts or complex or simple designs.

We have developed these products to perform well in any situation, and, to ensure they comply with the most stringent safety requirements, we have received UL certification of compliance for QMFZ2.E356537 Plastics – Component.

Contact us today to get the solar plastic molding and molded rubber components you need to produce and deliver quality solar panels.