Understanding the Process and Benefits of Rubber Molding

Rubber molding is a manufacturing process used in various industries, including the automotive and appliance sectors. At Clark and Rubber Plastic, our team helps shape materials with precision and high-quality performance. The process delivers reliable solutions to complex manufacturing needs. Here’s more information on the process and benefits of rubber molding: Rubber Molding Rubber molding […]

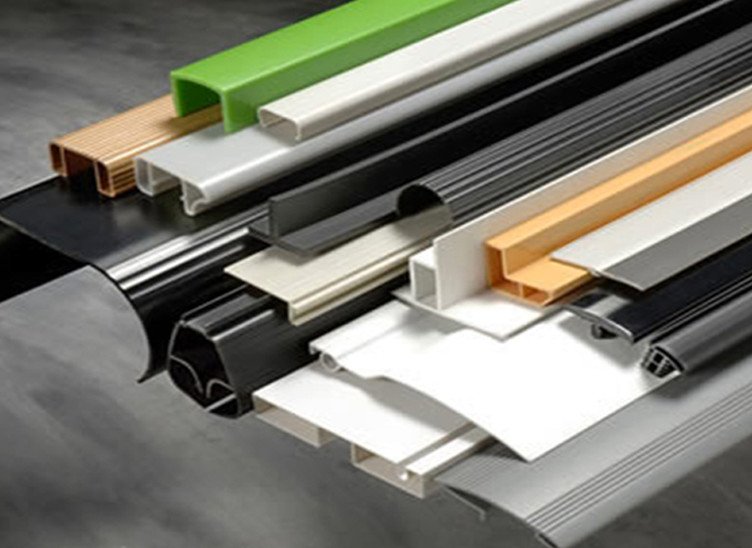

Exploring the Advantages of Plastic Extrusion for Custom Profiles

Custom components can be manufactured in multiple industries, including appliances, solar paneling, and more. The process is versatile for various products, such as customized profiles for consumer or automotive parts. At Clark and Rubber Plastic, our team specializes in high-quality processes that deliver precise and consistent results for small or large projects. Here are a […]

How To Choose a Suitable Rubber Molding Process

Choosing a suitable rubber molding process can improve the quality and performance of a product. Clark Rubber & Plastic helps clients choose a rubber molding process that will promote the integrity of their products. Here are some tips for choosing the proper molding process. Understand Your Project Requirements Defining your project’s needs can help you […]

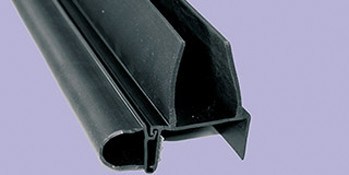

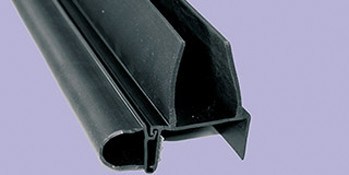

Unique Applications of Plastic Extrusion Across Industries

Plastic extrusion is a manufacturing process used in several industries, including automotive parts and appliance components. It involves creating high-quality plastic components like gaskets. Whether for military-grade applications or appliances, each tailored item can serve various purposes. At Clark and Rubber Plastic, we specialize in precision plastic extrusion, offering solutions for different industries. Here are […]

6 Tips for Working With a Rubber Molding Manufacturer

Working with a rubber manufacturer requires an understanding of their production processes and different specifications. After a good relationship has been established, you can receive products of consistent quality and have access to efficient manufacturing solutions at Clark Rubber and Plastic. Outlining project specifications, choosing the proper molding process, prioritizing quality control, and more will […]

How to Customize Plastic Parts Using Extrusion Techniques

Manufacturers can use plastic extrusion to create plastic components for the solar, appliance, automotive, and military industries. This includes wire insulation and pipes. Clark Rubber & Plastic offers plastic and rubber extrusion services. Here are several ways to customize plastic parts with extrusion techniques: Unique Molds for Die Cutting The plastic extrusion process works by […]

Three Questions To Ask Your Rubber and Plastic Manufacturer

A rubber or plastic manufacturer can help you create a high-quality custom rubber or plastic product. Services at Clark Rubber and Plastic include custom plastic and rubber molding. Here are three questions to ask your manufacturer: 1. What Are Your Capabilities and Services? When deciding on a manufacturer for your product, make sure that they […]

4 Reasons To Use Plastic Extrusion Services

Plastic extrusion allows companies across many industries to create custom parts for their products. At Clark Rubber and Plastic, we offer extrusion services to help customers create plastic goods of various colors, textures, thicknesses, and hardnesses. Here are four reasons to use plastic extrusion services: 1. Product Consistency Outsourcing your plastic part production to an […]