Design Considerations for Plastic Extrusion Profiles

Designing a plastic profile to fulfill the needs of your industry includes choosing characteristics and techniques. Clark Rubber and Plastic offers plastic extrusion services to create your profile. Here are several design choices for extrusion profiles:

Plastic Materials

Deciding what type of materials to utilize for the profile allows you to select the necessary attributes for your application. Multiple types of plastics can be extruded. This includes:

- High Impact Polystyrene: This is a thermoplastic styrene material. It is rigid and has high-impact attributes. High Impact Polystyrene is appropriate for creating parts for electronics, appliances, and the automotive fields.

- Polycarbonate: Polycarbonate is a strong polymer that has high transparency, temperature resistance, and gloss appearance. It is heat-resistant and moldable, and it can be used in profile forms. Extruded polycarbonate is utilized for protecting walls, refrigerators, and cabinets.

- Acrylonitrile Butadiene Styrene: ABS is an opaque plastic material used for indoor applications. It is moisture-resistant, lightweight, and resistant to corrosive chemicals. It is used for indoor applications in the construction, appliance, and furniture industries.

Material properties impact the performance of the part. UV stability, flame-retardant properties, and food-grade materials may be required depending on the industry. Clark Rubber and Plastic offers certified, high-quality components for plastic extrusion and makes recommendations for appropriate materials that fit your requirements.

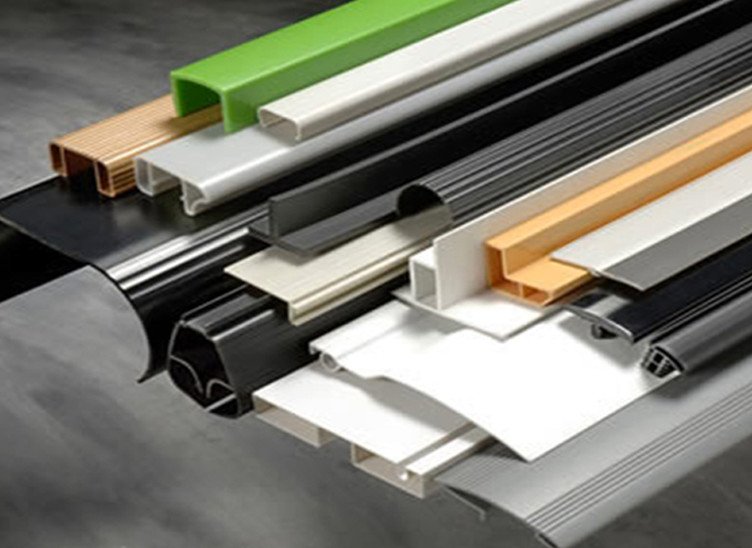

Profile Shaping

Choosing the shape for your plastic profile impacts the extrusion process. During the extrusion process, plastic pellets are melted in a chamber and moved through a filter to remove impurities. When leaving the barrel chamber, a hydraulic press pushes the melted plastic through a die to shape it. The die contains blades that cut the material into the product shape, and the shaping process via the die creates cross-sectional profiles. Clark Rubber and Plastic offers precision die-cutting services to create customized dies.

Extrusion is used to create customized profile features such as channels and edges. More complex profiles can result in shrinkage. To prevent this, designers are able to add more space to the die to accommodate the risk of shrinking.

Co-Extrusion and Tri-Extrusion Techniques

Co- and tri-extrusion technology is available to form complex plastic profiles. This process refers to extruding two or three polymers through a die to form a single cross-section. Co- and tri-extrusion combine materials with differing properties of density, thickness, and colors, enhancing the strength of the profile and fulfilling design requirements. This can help create a product that requires multiple characteristics, such as a rigid base and flexible edge. The machinery we utilize allows us to extrude the materials at different speeds, changing the thickness of the layers.

Learn More About Plastic Extrusion

Other design choices include color and finishes for your profiles. Colorants are added to the plastic mixture, and we offer a clear finish and crosshead extrusion coating to make the material stronger. Shearing on the production line creates uniform sizing for products. Clark Rubber and Plastic also creates extruded products for the military and defense, consumer, and solar industries. To learn more about plastic extrusion, we invite you to request a quote today.

Understanding the Plastic Extrusion Process and Its Industrial Applications

Plastic extrusion works with materials such as PVC, polypropylene, and polyethylene. Clark Rubber and Plastic is a rubber and plastic manufacturing company that utilizes extrusion techniques to create plastic films, sheets, and other products. Here is more information about the extrusion process and its industrial applications:

Melting and Die Shaping

To begin the plastic extrusion process, plastic pellets are fed into a heating chamber. Manufacturers can add customized colorants with the pellets, which allows for color uniformity for the products. We are able to use multiple colors in a project if needed.

Plastic pellets are melted down in the chamber, and a filter screen removes impurities. The material is then pushed through a metal die, which shapes the plastic with precise blades. Clark Rubber and Plastic offers precision die cutting and customized die molds to create specific shapes for your packaging, specialty parts, casing, and seals.

Extrusion Techniques

Companies utilize a variety of extrusion techniques to create different products. If your product requires multiple properties, such as a rigid base and a flexible edge, manufacturers can combine multiple polymers during the extrusion process. Companies such as Clark Rubber and Plastic offer co-extrusion and tri-extrusion options, allowing them to extrude two to three polymers simultaneously. Adding two polymers in a cross-section allows the manufacturers to create layers, and the machines can be adjusted to allow different thicknesses and sizes. Tri-extrusion utilizes three extruders and materials.

Co-extrusion and tri-extrusion help save time and enhance properties such as strength, sturdiness, surface performance, and flexibility. Increased durability is beneficial for parts for military vehicles, as they will be used in extreme conditions.

Other extrusion techniques include tubing, blow film, sheet, and over-jacketing extrusion. Tubing extrusion creates medical and plumbing tubes by pushing internal pressure through the plastic, creating a hollow core. Blow film extrusion uses a circular die to create thin films for shopping bags, and sheet extrusion forms a flat, continuous sheet that can be put through cooling rolls to create different thicknesses. Sheet extrusion creates packaging materials and signs. Over-jacketing is used to protect cables and wiring by adding a layer of plastic over the product.

Cooling and Cutting

Cooling the product after it is shaped finalizes the form of the product. A belt pulls the plastic through a trough with a cool water bath. To maintain the shape of a plastic pipe, a designer can add a vacuum to the bath. A sizing belt then moves the plastic to a blade that cuts the plastic to form individual products.

Industrial Areas

Extrusion is able to create high-performing products used in various sectors. Manufacturers such as Clark Rubber and Plastic work with industries such as the consumer, appliance, and solar sectors. Plastic covers for food and cosmetics in the consumer industry prevent airborne contamination, and cable insulation protects wiring for fridges. Extruded clamps for solar panels are able to resist temperature changes.

Learn More About Plastic Extrusion

We can include finishes and additives to add fire-retardants and UV stabilizers to your product. To cut, drill, or coat your profile, we offer CNC turning and milling, and other secondary processes. Clark Rubber and Plastic is able to work with you for both high- and low-volume projects. We utilize dual-durometer, military-approved plastic materials. To begin a plastic extrusion project, we invite you to request a quote today.

The Future of Plastic Extrusion

Plastic extrusion involves innovation in both equipment design and process control. Extruder systems can offer multi-layer and co-extrusion profiles, which handle higher throughput and precision. At Clark Rubber and Plastics, our team has integrated additional extrusion lines and rubber molding production capabilities in a 40,000-square-foot facility. Here is some information about the future of plastic extrusion:

Material Innovation and Sustainable Practices

One key trend in plastic extrusion and rubber molding involves the development of materials. This includes bio-based polymers, recycled content, and advanced resin systems. Because sustainability initiatives prioritize environmental goals, these factors are now helping reshape extrusion processes. Manufacturers may be increasing recyclability, and they have the option to incorporate alternative feedstocks. Recycled materials include modified screw designs, adjusted cooling profiles, or new die geometries.

Integrating sustainable materials and closed-loop processes becomes a key differentiator. Companies should adapt their extrusion capacity to handle mixed or reclaimed resins, so they can maintain a strong competitive edge in the market. When the technological enhancements are complete, our team at Clark Rubber and Plastics will operate six new extrusion lines to support a wide range of geometries and sustainable practices.

Industry Digitalization and Smart Manufacturing

Industry digitalization and smart manufacturing include IoT (Internet of Things) sensors. Machine learning derived analytics provide predictive maintenance, and this makes sure automated adjustments are applied to the equipment. It allows data-driven control systems, which leverage real-time feedback on various factors. The data should include melt pressure, temperature profiles, die swell, and material flow, which are key factors in quality control.

Extrusion facilities can reduce downtime, improve consistency, and optimize throughput; this digital layer is key to modern manufacturing. It also supports traceability and quality assurance. These production lines and equipment help provide rubber parts for the automotive and consumer industries.

Customized Profiles and Industry Applications

Plastic extrusion is key to producing continuous profiles, such as seals, channels, tubing, or complex cross sections. The industries that benefit include the appliance and solar sectors. Each mold offers customized properties, so the finished parts may have higher strength or an improved surface finish. The role of custom extrusion provides design flexibility and material layering, and clients require this complexity because their product applications are becoming more specialized. Multi-layer extrusion allows for combining functional layers, like conductive or insulating, in one profile.

Future Challenges and Opportunities

Material volatility and advanced processes offer challenges for feedstock; this may affect the regulatory pressure for sustainable content. It often requires advanced process controls. The challenges create opportunities, such as manufacturers that invest in flexible extrusion systems, upgrading tooling, or automated monitoring. Because the market environment is changing, partnerships across supply chains gain a strategic edge and the ability to adapt quickly to new materials and technologies. This helps them deliver precise custom profiles and disintegrate digital analysis for future growth.

Use Rubber Molding and Plastic Extrusion

The future of plastic extrusion involves advanced equipment, new materials, digital enhancements, and strategic responses. As manufacturers adopt smarter machines and design processes, extursion continues to benefit an array of applications across multiple industries. At Clark Rubber and Plastics, our team offers various customization options for unique solutions. Contact us today to learn more about rubber molding and extrusion processes.

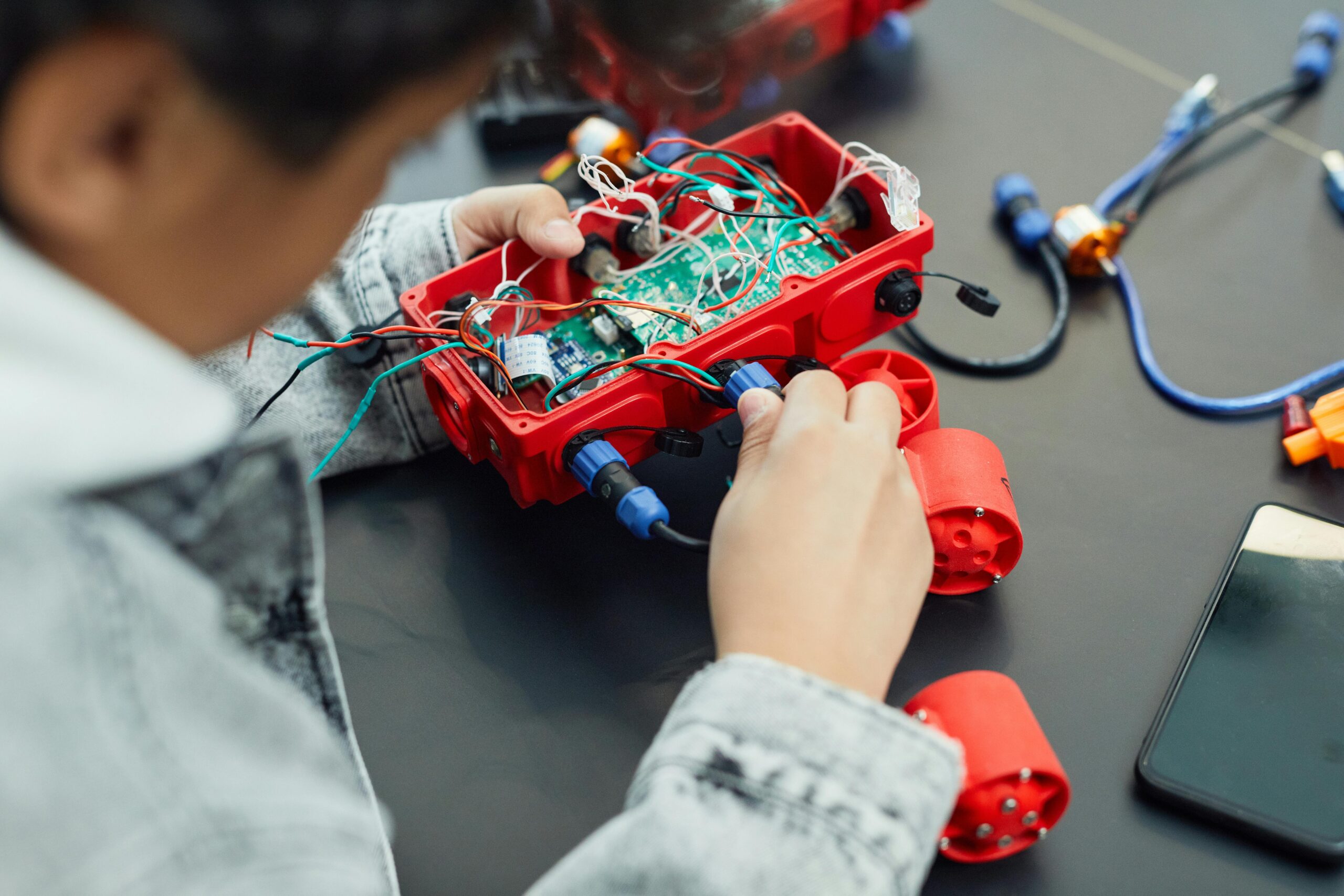

Customization Opportunities in Plastic Extrusion

The extrusion process is used in manufacturing because it’s versatile and efficient for producing components of various shapes and sizes. These parts can be customized for various applications across different industries, including consumer products and precision parts for appliances and industrial equipment. At Clark Rubber and Plastic, the process is about delivering custom solutions to meet standards for shape, durability, and performance. Here’s more information about the customization opportunities in plastic extrusion:

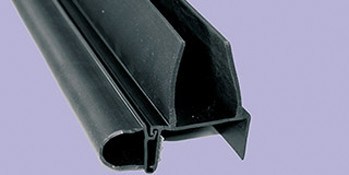

Custom Profiles

One customization opportunity in plastic extrusion is the design of the profile. Standard shapes are helpful, but certain applications require parts with unique contours or cross-sections. Whether it’s a seal, gasket, or guide rail, the ability to develop a custom profile makes sure the component integrates seamlessly into the final product.

Our team at Clark Rubber and Plastic designs and manufactures custom extrusion dies. Doing this in-house allows clients to specify dimensions, wall thickness, and geometry. This level of control is key when working with appliances, where space constraints and functional requirements demand an exact fit. In the consumer industry, custom profiles support the final design while maintaining a consistent quality.

Material Selection

The material selection influences the performance of an extruded part. Customization at this level makes sure the finished component can handle its intended use. There’s a wide variety of thermoplastics, each suited to particular applications. This includes high-impact, high-heat, or chemical-resistant environments. Some components used in the appliance industry often require flame-retardant properties or UV stability. Others may need food-grade materials or low-friction surfaces.

Co-Extrusion Components

Some parts require more than one material to function effectively. Co-extrusion provides a solution for materials to be extruded into a single, uniform profile. This helps create components with dual or even triple characteristics. A part might need a rigid base for structural support and a soft, flexible edge. Rather than assembling multiple parts, co-extrusion bonds different materials together during the manufacturing process. At Clark Rubber and Plastic, our team uses co-extrusion to combine strength, flexibility, and surface performance in a single pass. This saves time and makes sure the component has structural integrity.

Post-Extrusion Fabrication

Post-extrusion fabrication services enable components to be further tailored through punching, drilling, cutting, or notching. These steps prepare the part for assembly or installation. It also doesn’t require additional handling by the customer. An in-house fabrication process should enable teams to produce parts that arrive ready for installation. Whether it’s a slotted profile for a track system or holes for fasteners, this end-to-end approach supports industries where accuracy, turnaround, and simplicity are key.

In industries such as automotive or appliances, custom extrusion helps reduce wear. If components are in constant use for heat cycles or mechanical stress, a mold will enhance efficiency. Whether it’s creating a part with tight tolerances or adjusting wall thickness to support airflow, an in-house, experienced team will provide quality parts.

Try Plastic Extrusion With Clark Rubber and Plastic

The extrusion process provides materials, engineering, design, and a platform for delivering custom parts. At Clark Rubber and Plastic, customization is built into the process, from the initial concept to the final production. Contact our team today to discover the customization options we offer for various industries, including automotive, military, and more.

How To Choose the Right Plastic Extrusion Techniques for Your Project

Plastic extrusion refers to the process of melting and forming plastic with a custom die. The plastic is pushed through a die that shapes the material, and the resulting form is then cooled and cut to size. Clark Rubber and Plastic uses extrusion techniques to create high-quality plastic products. Here are some factors that affect which plastic extrusion technique you should use for your project:

Product Type

Different plastic extrusion techniques produce a range of products. Knowing what products you need for your project will help you determine the most effective technique. Our extrusion techniques can help you create:

- Plastic films: Blow film extrusion works by extruding plastic through a circular die, creating a tube. The machine blows air into the tube to form the correct size and dimensions. This tube creates thin plastic films.

- Plastic sheets: Sheet extrusion uses a flat die to shape molten plastic into flat sheets. Cooling rolls allow manufacturers to control the thickness of the sheets.

- Tubes and pipes: The tubing extrusion technique applies a positive internal pressure throughout the plastic, creating a hollow core. This results in plastic tubes and pipes that can be used for plumbing and medical devices.

- Cable insulation: The over-jacketing technique creates a protective outer layer for cables and wires. Melted plastic is pressed around a cable to enhance its insulation and protect future handlers from electric shock.

These extrusion techniques create products with uniform sizes and dimensions. They also enable you to customize your products to meet your project requirements. Our team will discuss your project goals to help you select an extrusion method that aligns with your product designs and material preferences.

Industry Niche

Your business’s industry impacts the type of plastic products and extrusion methods you’ll need. Industries we serve include the home appliance, consumer, and automotive industries. The tubing extrusion technique can be used to create vehicle hoses and tubing for fluid transfer systems in automobiles. The home appliance industry utilizes plastic components for handles and seals on ovens, cooktops, and microwaves. Co-extrusion and tri-extrusion techniques combine two or three materials in a single product, resulting in a final product with unique strength and durability.

Packaging for consumer products often requires plastic films and sheets that facilitate easy transportation and product preservation. Sheet and blow film extrusion techniques can be used to create packaging products like grocery bags and cling wraps. These materials provide product protection and extend the shelf lives of foods. Plastic extrusion allows for more product versatility, allowing you to create packaging with different surface finishes and barrier properties.

Thickness Requirements

Extrusion processes can produce plastic goods with varying thicknesses. Sheet extrusion can be used to create thicker plastic films than blow film extrusion. At Clark Rubber and Plastic, we use co-extrusion and tri-extrusion to create multiple layers within individual products. We utilize tri-extrusion to manufacture pipes and tubes, and we confirm that the outer layers of these products provide lasting environmental protection.

Learn About Plastic Extrusion Techniques

Materials we use for our plastic extrusion products include thermoplastics, elastomers, acrylic, and polycarbonate. We add color to plastic products by mixing in colorants during the melting process. Clark Rubber and Plastic alsooffers plastic injection molding and rubber extrusion services. To learn more about our plastic extrusion techniques, call or email us today.

Exploring the Advantages of Plastic Extrusion for Custom Profiles

Custom components can be manufactured in multiple industries, including appliances, solar paneling, and more. The process is versatile for various products, such as customized profiles for consumer or automotive parts. At Clark and Rubber Plastic, our team specializes in high-quality processes that deliver precise and consistent results for small or large projects. Here are a few advantages of plastic extrusion for custom profiles:

Design Versatility

One advantage of plastic extrusion is its flexibility in design. The process helps produce complex cross-sectional profiles, allowing manufacturers to create custom shapes to meet exact specifications. Whether it’s for tubing, edging, seals, or intricate components, extrusion offers a variety of designs. Some products are made for airplanes or aerospace applications. Other options include automotive plastics, armaments, and solar plastics.

Material Options

Various material options suit any application. These materials include PVC, polyethylene, polypropylene, and thermoplastic elastomers. Each material offers unique features and advantages, such as flexibility, chemical resistance, durability, or temperature tolerance. Some applications might require lightweight materials for easier handling and durability in tough conditions. At Clark and Rubber Plastic, our team of experts helps select the best material for performance requirements and industry standards. Whether the focus is on strength or weather resistance, we’ll assist with a solution.

Quality and Performance

Consistency is key when manufacturing custom profiles, like automotive or military. Components used in the military are produced to a high standard so that they remain durable during daily use in harsh conditions. Minor variances may impact product performance. Plastic extrusion provides a steady, repeatable output that makes sure there is uniformity across every piece produced. Advanced equipment and quality control processes can offer tight tolerances and reliable performance. Other options include a balance of strength and weight. From cable trays for solar panels to sealing solutions in military equipment, custom extrusion helps deliver strength, durability, and longevity.

Custom Finishes

Another advantage of plastic extrusion is the ability to customize finishes and include additives. This includes UV stabilizers, flame retardants, color matching, and texture adjustments. These features may be incorporated during the extrusion process. Each product can be visually appealing and optimized for its intended use.

The extrusion process can be compatible with a wide range of secondary options. This includes how profiles may be cut, punched, drilled, coated, or assembled into more complex components. These custom secondary services include precision die-cutting, CNC turning, milling, and other additional processing. This integrated approach helps simplify supply chains to enhance the functionality of a finished product.

Use Plastic Extrusion With Clark and Rubber Plastic

At Clark and Rubber Plastic, our team has years of experience in plastic extrusion services, supporting a wide range of industries. Our team can create custom profiles to match exact requirements. Whether clients need small batch products, support for design refinement, or processing to meet product requirements, our team helps deliver. We combine state-of-the-art technology and hands-on craftsmanship to create a wide range of products, including sealants. Contact us today to learn more about the advantages of custom extrusion processes and how we can create a product for your project.

Unique Applications of Plastic Extrusion Across Industries

Plastic extrusion is a manufacturing process used in several industries, including automotive parts and appliance components. It involves creating high-quality plastic components like gaskets. Whether for military-grade applications or appliances, each tailored item can serve various purposes. At Clark and Rubber Plastic, we specialize in precision plastic extrusion, offering solutions for different industries. Here are some unique applications of the process:

1. Automotive Industry

Components created by Plastic extrusion help companies in the automotive industry make quality vehicle elements. This includes high-performance parts that withstand heat and wear and tear. Extruded pieces, like rubber inserts, contribute to more modern, lightweight designs. If a vehicle weighs less, it can improve fuel efficiency for the driver and reduce production costs for the manufacturer. Seals and weatherstripping are other applications that are extruded, and they prevent water, dust, and noise from entering vehicles. Wire harness tubing protects electrical writing from extreme heat or cold temperatures. Other components, such as dashboards, are custom-made for durability.

2. Appliance Industry

Modern appliances, such as refrigerators, can use extrusion for functional parts for items like door gaskets, which are airtight seals. These parts help improve energy efficiency and regulate the internal temperature to keep stored food safe for consumption. Other covered parts are flexible wire and cable insulation. This keeps the wire’s electrical components safe and secure. Here are some other appliance parts:

- Ice maker dispensers

- Trim and edging

- Hoses and tubing

- Casings

3. Consumer Industry

Protective covers for daily consumer products like food or cosmetics may help store them safely for a period of time. Packaging materials help prevent airborne contaminants or bacteria from entering these items, making them unsafe for customers. Environment-resistant covers include shields that also limit damage to electronic devices. With advanced techniques, Clark and Rubber Plastic manufacturers help produce high-quality, durable products to help other product-based companies be successful.

4. Military and Defense Industry

Extruded pieces used for military applications are required to have durable properties. These include components for airplanes, tanks, aerospace insulation, armaments or munitions, and more. As military members may be in life-threatening situations, components need to perform as expected and on demand. Parts should also be capable of keeping out sand, dust, and mud. Custom military parts provide higher levels of functionality and quality, such as for marine vessels like aircraft carriers, ships, submarines, and sonar buoys.

5. Solar Industry

Plastic and rubber items, such as clamps or rubber inserts, are designed for solar operations. These are customized to be sturdy, efficient, and resilient for solar panels that undergo extreme temperature fluctuations. Professionally developed wire management systems keep cords organized and secure. Other sealing solutions, like cable trays or inserts, prevent moisture and dust from damaging components.

Using plastic and rubber materials, our Clark and Rubber Plastic team implements materials such as EPDM (Ethylene Propylene Diene Monomer), TPV (Thermoplastic Vulcanizates), or SBR (Styrene Butadiene Rubber). Other plastics might include Viton®, HDPE, or Polycarbonate. We use a full range of thermoplastics and other materials, including RPVC, Provista, Sarlink, ASA, for customized parts.

Use Plastic Extrusion With Clark and Rubber Plastic

At Clark and Rubber Plastic, our manufacturing process serves multiple industries, including healthcare and medical machinery. We also provide custom solutions for construction, plumbing, electronics manufacturers, and industrial productions. Our plastic extrusion process helps enhance components’ durability, efficiency, and performance. Contact our team today to learn how we can custom-design parts or meet your business’s unique needs.

How to Customize Plastic Parts Using Extrusion Techniques

Manufacturers can use plastic extrusion to create plastic components for the solar, appliance, automotive, and military industries. This includes wire insulation and pipes. Clark Rubber & Plastic offers plastic and rubber extrusion services. Here are several ways to customize plastic parts with extrusion techniques:

Unique Molds for Die Cutting

The plastic extrusion process works by melting plastic pellets and pushing the material through a metal die. Metal dies have sharp, high-precision blades that cut and shape the plastic. A cold water bath cools the plastic, and the sizing belt and blade cut the plastic into individual parts. Die cutting can be used with multiple types of plastic, including polyethylene and polyvinyl chloride.

The metal die shapes the plastic according to specific dimensions. A plastic manufacturer can create a customized die mold that aligns with your particular product requirements. Using a unique die allows manufacturers to create customized plastic shapes for various industries and uses. This includes the distinctive shapes required for product packaging and the casing and seals for appliances. It also allows the manufacturer to create specialty parts. Clark Rubber & Plastic offers customized die molds and precision die-cutting services.

Custom Colors for Products

Colorants are mixed into the raw materials to color a plastic extrusion product. The melting process allows the plastic pellets to combine with colorants. This coloring process allows all the parts to be the same color, creating a uniform appearance. You can choose a custom color for your products. We can also combine multiple colors in a single project.

Co-Extrusion Process for Different Materials

Different materials have varying thicknesses and durability. Using two or more materials in a plastic component allows you to build a complex product with multiple properties. The co-extrusion process can help you customize the component to fulfill the necessary performance requirements, such as enhancing the component’s strength and sturdiness. This can be helpful when creating plastic parts used in military vehicles and armaments. These parts are held to high standards for durability, as they are required to withstand extreme conditions. Our high-quality production system helps make sure all of our products meet high safety and production standards.

Co-extrusion also allows manufacturers to combine two polymers into a cross-section to create different layers. The materials are extruded at the same time. The extruding machines can be set to various speeds to change the layers’ thickness. We can also combine three polymers through tri-extrusion, which uses three extrusion processes. Our team members at Clark Rubber & Plastic offer recommendations on what type of materials are appropriate for your product.

Plastic Extrusion at Clark Rubber & Plastic

We use tubing, blow film, and sheet extrusion processes to create uniform tubes, thin films, and plastic sheets. From prototyping to high-level production, Clark Rubber & Plastic provides fast turnaround times for plastic extrusion projects. We also offer milling, digital printing, and packaging services for your products. An online form is available on our website to request a quote. To learn more about the extrusion techniques at Clark Rubber & Plastic, call us today.

- 1