4 Reasons To Use Plastic Extrusion Services

Plastic extrusion allows companies across many industries to create custom parts for their products. At Clark Rubber and Plastic, we offer extrusion services to help customers create plastic goods of various colors, textures, thicknesses, and hardnesses. Here are four reasons to use plastic extrusion services:

1. Product Consistency

Outsourcing your plastic part production to an extrusion professional allows you to achieve consistency across all batches. You can give a plastic manufacturer your plan, and they will create parts to match your specifications. At Clark Rubber and Plastic, we have extruders with instrumentation that measures the plastic’s temperature and thickness to maintain consistency across all products. This machinery also detects the pressure of the extruder screw to confirm each part is produced at the same rate with the same amount of force.

2. Precise Dimensions

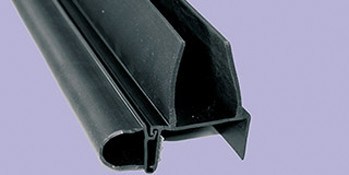

A plastic extrusion company creates custom dies for each of your parts. The die is a metal disc that has custom shapes cut into it. Melted plastic moves through the die and cools to create the unique shape or profile your company needs. The high-precision tolerance levels in our machines result in products with dimensions that closely match their original manufacturing plans. Before creating your die and beginning production, our team will discuss your product’s application and recommend design changes and material types that will make your final products as effective as possible.

3. Customization Options

Producing plastic parts with extrusion allows you to customize the final product’s size, density, and color. We carry a range of plastic types to provide customers with options for the flexibility and durability of their final product. Clark Rubber and Plastic offers military-grade and UL-approved materials to confirm the quality of your components. We can combine materials of various colors and properties to produce a fully customized part.

Our dual-durometer production process involves combining two plastic types with varying hardness levels to achieve a final product with the characteristics of both materials. Components made with dual-durometer extrusion include seals, impact absorbers, and sound dampeners. Our team assesses your project goals to help you determine which plastic type and production method is right for you.

4. Quick Production

Extrusion services speed up the manufacturing processes by assigning a key task to a professional facility that handles high-volume orders. Once you receive your custom parts, your team is only responsible for assembling and packaging the final products. At Clark Rubber and Plastic, we use extruders with barrels and tips that hold large batches of melted plastic and automatically direct it into the die. This machinery allows us to produce high-volume orders of plastic parts and prototypes.

Explore Plastic Extrusion Services

Clark Rubber and Plastic offers extrusion services to help companies produce custom profiles, shapes, and forms. We use a variety of plastic materials, including RPVC, neoprene, acrylic, and nitrile. Our facility has multiple extrusion lines that allow us to produce high-quality products quickly. Contact us today to learn more about our plastic manufacturing services and receive a free quote for your extrusion project.