Design Considerations for Plastic Extrusion Profiles

Designing a plastic profile to fulfill the needs of your industry includes choosing characteristics and techniques. Clark Rubber and Plastic offers plastic extrusion services to create your profile. Here are several design choices for extrusion profiles: Plastic Materials Deciding what type of materials to utilize for the profile allows you to select the necessary attributes […]

Understanding the Plastic Extrusion Process and Its Industrial Applications

Plastic extrusion works with materials such as PVC, polypropylene, and polyethylene. Clark Rubber and Plastic is a rubber and plastic manufacturing company that utilizes extrusion techniques to create plastic films, sheets, and other products. Here is more information about the extrusion process and its industrial applications: Melting and Die Shaping To begin the plastic extrusion […]

The Future of Plastic Extrusion

Plastic extrusion involves innovation in both equipment design and process control. Extruder systems can offer multi-layer and co-extrusion profiles, which handle higher throughput and precision. At Clark Rubber and Plastics, our team has integrated additional extrusion lines and rubber molding production capabilities in a 40,000-square-foot facility. Here is some information about the future of plastic […]

How To Optimize Production Efficiency in Rubber Molding Operations

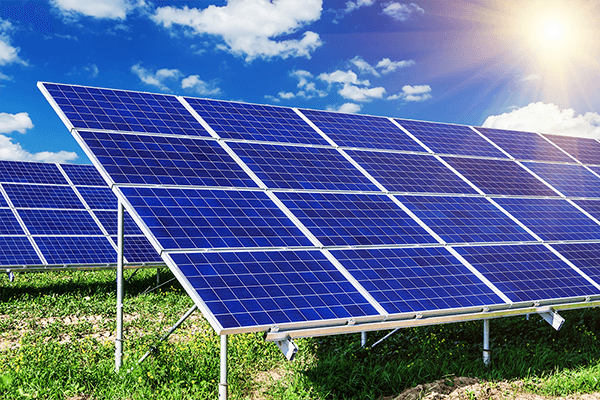

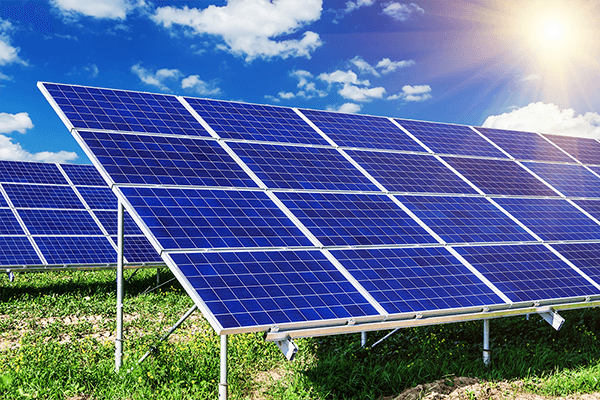

Rubber molding allows you to create parts with precise dimensions and complex shapes. It’s a valuable process for making items such as rubber hoses, seals, and medical devices. At Clark Rubber and Plastic, we manufacture parts for many different industries, including solar and automotive. Here are some tips for optimizing production efficiency in rubber molding operations: […]

How to Select Material in Rubber Molding Processes

When manufacturing high-performance components, selecting the right material is a key step in the rubber molding process. The material affects the component’s durability and determines its ability to withstand harsh conditions, such as extreme temperatures or UV exposure. At Clark Rubber and Plastic, we help manufacturers develop custom molded solutions that meet specific functional requirements. […]

Understanding the Role of Rubber Molding in Automotive Applications

Rubber molding is a manufacturing process that produces custom rubber parts tailored for various industries, like automotive businesses. It delivers components to vehicle manufacturers, and it may improve performance and safety. At Clark Rubber & Plastic, we specialize in manufacturing rubber and plastic extrusion, helping businesses have high-quality products. Here’s the role of rubber molding in […]

Customization Opportunities in Plastic Extrusion

The extrusion process is used in manufacturing because it’s versatile and efficient for producing components of various shapes and sizes. These parts can be customized for various applications across different industries, including consumer products and precision parts for appliances and industrial equipment. At Clark Rubber and Plastic, the process is about delivering custom solutions to […]

How To Choose the Right Plastic Extrusion Techniques for Your Project

Plastic extrusion refers to the process of melting and forming plastic with a custom die. The plastic is pushed through a die that shapes the material, and the resulting form is then cooled and cut to size. Clark Rubber and Plastic uses extrusion techniques to create high-quality plastic products. Here are some factors that affect […]