3 Uses of Custom Rubber Molding

Customized orders for appliances, consumer products, or automotive can be created at Clark Rubber and Plastic. Using natural and synthetic rubbers, we produce industry-specific parts in high or low-production quantities and of high quality. Modern technology has improved rubber production and has added synthetic rubber fitting specific needs including weather and chemical resistance. Here are […]

What is Rubber and Plastic Extrusion?

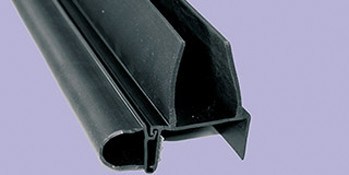

Extrusion molding can be used to make pipes and tubing, tracks, hoses, and drinking straws. Clark Rubber and Plastic offers two versatile material options for extrusion molding. Learn more about rubber and plastic extrusion, which options are right for your project, and how to use extrusion services: Extrusion Process Extrusion molding is a manufacturing process […]

How Does Plastic Extrusion Work?

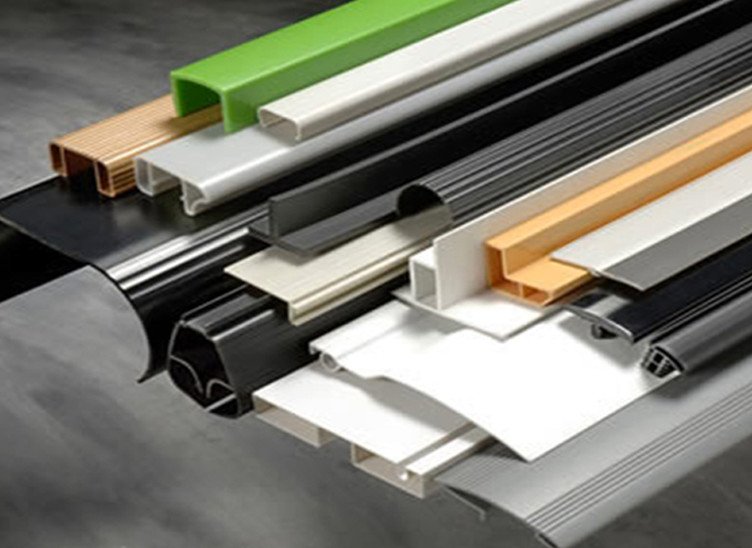

Plastic extrusion involves melting plastic into solid, finished products such as pipes and tubing. Understanding how extrusion methods work helps determine which technique fills a business’s needs. Some processes include co or tri-extending, which can produce a wide variety of shapes, forms, and textures. At Clark Rubber and Plastic, we provide plastic extrusion services for […]

What Is Rubber Molding?

When manufacturers design products and machinery that require intricate pieces, they use the versatile rubber molding process to create them. Clark Rubber & Plastic uses this process to create custom parts for a range of industries. Here’s more information about the molding process and how it works: Molding Overview Rubber molding is a manufacturing process […]

Different Plastic Extrusion Techniques

Plastic extrusion is a high-volume manufacturing process that involves pushing melted plastic through a die so that the plastic takes on a new shape. This process can create a wide range of plastic products with various shapes, profiles, sizes, and properties. It is also highly customizable and cost-effective, making it a good option for large-scale […]

Exploring the Benefits of Plastic Extrusion

Plastic extrusion is a manufacturing process that produces a wide variety of plastic profiles, forms, and shapes. These shapes are created by running melted plastic through an opening in a die and trimming the product to the desired length. At Clark Rubber and Plastic, our services are used in various industries, including solar, consumer, appliances, […]

What Are Specialized Rubber Molding Services and How Can I Use Them?

Specialized rubber molding services turn raw materials into usable consumer products. These processes craft rubber into small and large components like gaskets and rubber mats. Molding services are used in many industries, like automotive, solar, and home appliance manufacturing. Here is more information about custom molding services and how businesses can use them: Specialized Rubber […]

Understanding the Rubber Molding Process

At Clark Rubber and Plastic, our rubber products go through a specific process to make sure they are dependable and durable. We want our customers to understand how the rubber molding process works and where you can use them. Here are some methods of how rubber molding is created: Molding Basics Molding is a versatile […]